This Assam Duo Is Turning Water Hyacinth Into Tree-Free Paper — And Has Already Made Rs 20 Lakh

The floating aquatic weed known as the Terror of Bengal is now the raw material behind Assam’s latest innovation. A handmade paper brand is using water hyacinth — an invasive plant species that’s often seen as a menace — to create something meaningful and eco-friendly.

“We have named it Kumbhi Kagaz because it comes from jala kumbhi, Sanskrit for water hyacinth,” says Rupankar Bhattacharjee, co-founder of the Assam-based startup behind the paper brand.

Handmade paper has already been made from cotton waste, banana fibre, and even elephant dung. But this one stands out. Kumbhi Kagaz is currently in the process of getting an Indian patent, and is made using only water hyacinth pulp, without the use of any chemicals.

Water hyacinth is harvested from wetlands across Assam, including Pub Mongoldoi and Deepor Beel, and used as the sole raw material in KKPL’s paper.

Water hyacinth is harvested from wetlands across Assam, including Pub Mongoldoi and Deepor Beel, and used as the sole raw material in KKPL’s paper.

Water hyacinth, locally known as pani meteka, is widely available across Assam. Its stems and roots spread across water bodies in many parts of the state, including the wetlands of Pub Mongoldoi in Darrang district and Deepor Beel, Assam’s only Ramsar site.

Districts such as Kokrajhar, Dhemaji, Nagaon, Tinsukia and Majuli also see widespread growth of the plant, which has long been a concern in the region. The free-floating weed is known to cover large parts of water bodies, choking them and depleting oxygen levels. This blocks sunlight and kills aquatic life.

Water hyacinth, often called the ‘Terror of Bengal’, chokes waterbodies across Assam and disrupts aquatic ecosystems.

Water hyacinth, often called the ‘Terror of Bengal’, chokes waterbodies across Assam and disrupts aquatic ecosystems.

It’s for this reason that water hyacinth is often referred to as the Terror of Bengal. But now, through a blend of innovation and sustainability, this invasive species is being transformed into a valuable resource.

100 percent chemical-free handmade paper

Enter two passionate youths from Guwahati — Rupankar Bhattacharjee (27) and Aniket Dhar (24), who saw an opportunity in a challenge. Together, they founded Kumbhi Kagaz Pvt. Ltd (KKPL), a startup that produces 100% tree-free, biodegradable, blot-free, and chemical-free handmade paper using the invasive meteka plant, also known as water hyacinth.

KKPL was co-founded by Rupankar Bhattacharje and Aniket Dhar, who turned Assam’s water hyacinth crisis into an opportunity.

KKPL was co-founded by Rupankar Bhattacharje and Aniket Dhar, who turned Assam’s water hyacinth crisis into an opportunity.

“While releasing a rescued python in the wild, I learned about water hyacinth and its detrimental effect on our water bodies,” says Rupankar, a wildlife enthusiast and member of the NGO Help Earth. “The famous herpetologist Jayaditya Purkayastha, who subsequently served as our mentor, expressed his annoyance with this invasive aquatic plant that has been wreaking havoc on our waterways.”

Under Dr Purkayastha’s guidance, Rupankar started researching the plant’s chemical composition. He discovered that water hyacinth is a lignin-poor plant, with over 85% cellulose and hemicellulose components that make it a strong candidate for papermaking. Using a DIY approach, he began experimenting with handmade paper production during the COVID-19 lockdown and successfully created prototypes.

Around the same time, Rupankar, Aniket, Dr Purkayastha, and two others co-founded The Inside Out programme, which focused on trekking, conservation storytelling, and biodiversity research. Through this initiative, they connected with a community of people invested in the environment, many of whom would later support their paper-making journey.

In 2021, their efforts paid off when they won the UK-based WasteAid Organisation’s “Zero Waste Cities Challenge — Guwahati” and secured a grant of €10,000. The challenge aims to support entrepreneurs turning waste into sustainable solutions while creating green jobs. The following year, the team also won the Tide 2.0 title by Assam Downtown University Venture Labs and the India Pitch Pilot Scale Startup Challenge.

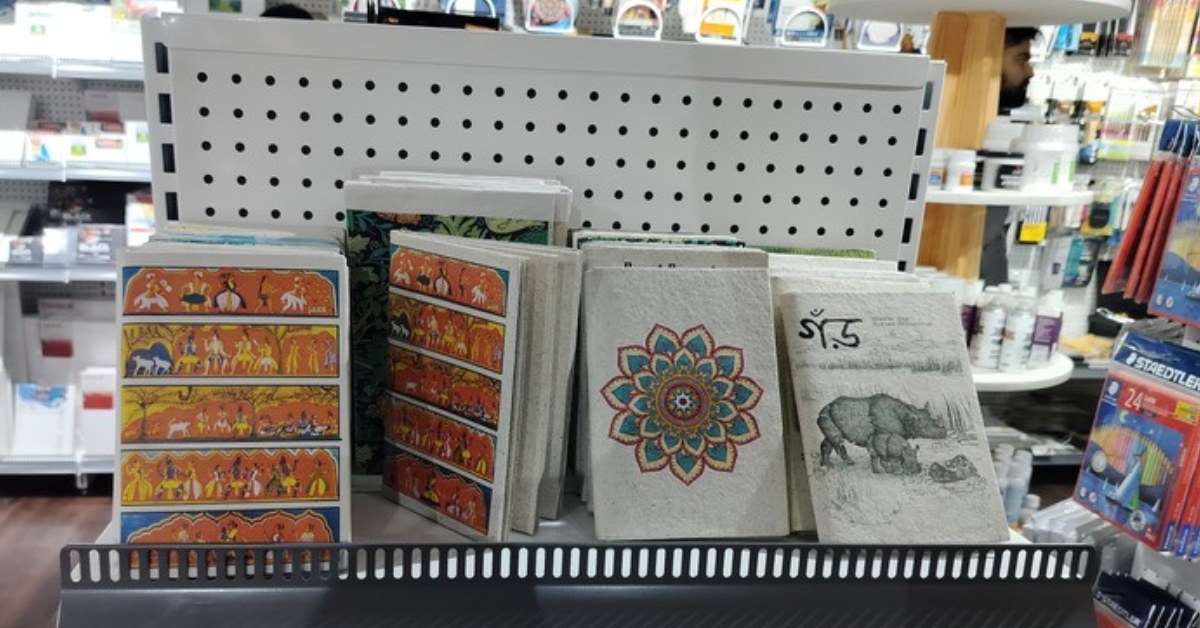

Handmade products made from Kumbhi Kagaz paper — tree-free, chemical-free, and created using water hyacinth pulp.

Handmade products made from Kumbhi Kagaz paper — tree-free, chemical-free, and created using water hyacinth pulp.

By early 2023, they launched their business through an online store and B2B connections, receiving encouraging feedback for their tree-free paper alternative. So far, KKPL has received grants totalling Rs 35 lakh to further develop and grow their work.

Less water, more impact: rethinking paper with just four steps

“We are not into eliminating the water hyacinth but do controlled harvesting, as the waterbodies where it grows are hiding spots for birds like the whistling duck. Swamp-beside jacanas lay eggs there, and munias nest in the reeds,” explains Dr Jayaditya Purkayastha.

Unlike other handmade papers that undergo 12 steps, Kumbhi Kagaz uses just four — from dry mass to paper. While conventional A4 paper requires 15 to 20 litres of water to produce, KKPL’s method uses only two litres. At present, KKPL produces around 1,000 A4 sheets a month. Although their machines can handle up to 2,500 sheets, limited drying capacity has slowed down full-scale production.

Earlier, limited space for drying water hyacinth in Guwahati slowed production — a challenge resolved with their expansion to Kaziranga.

Earlier, limited space for drying water hyacinth in Guwahati slowed production — a challenge resolved with their expansion to Kaziranga.

To date, the team has processed over 92 tonnes of water hyacinth into biodegradable paper sheets.

To date, the team has processed over 92 tonnes of water hyacinth into biodegradable paper sheets.

“In 2023, we had the opportunity to meet the Prime Minister, and we were even mentioned in his Mann Ki Baat. This year, during Advantage Assam 2.0, the PM visited our stall on February 24,” shares Aniket Dhar, the co-founder.

In late 2024, the team faced a major setback when an electrical failure damaged most of their machinery, forcing them to miss a crucial corporate sales season. However, in January this year, with support from Dr Sonali Ghosh, IFS and Field Director of Kaziranga, they secured an opportunity to expand operations in the region. This new phase aims to involve and empower local farmers and artisans from wetland communities.

Kumbhi Kagaz’s expansion to Kaziranga aims to involve local farmers and wetland artisans in sustainable paper-making.

Kumbhi Kagaz’s expansion to Kaziranga aims to involve local farmers and wetland artisans in sustainable paper-making.

They also plan to launch a new facility in Goalpara soon. Earlier, space constraints for drying paper had limited them in Guwahati, but the move to Kaziranga has resolved this issue.

India’s handmade paper industry is currently valued at $2.5 billion and is projected to grow to $10 billion by 2030. Over the last two years, KKPL has made sales worth Rs 20 lakh and has converted 92 tonnes of water hyacinth into handmade paper.

To date, the team has processed over 92 tonnes of water hyacinth into biodegradable paper sheets.

To date, the team has processed over 92 tonnes of water hyacinth into biodegradable paper sheets.

The current cost of manufacturing an A4 sheet is ₹15, but after expansion, they aim to bring this down to ₹1. From producing 16,000 sheets a day, they plan to scale up to 40,000 sheets daily.

“We are confident of becoming a game-changer,” says Rupankar. “We have access to a readily available raw material. Plus, our product has a low water footprint, is printer-friendly, and is excellent for watercolour artists.”

Edited by Leila Badyari Castelino; All images courtesy KKPL

News